Both of those isolator and RABS deliver physical barriers to guard the item as well as the employee from probably hazardous chemical substances. They are sometimes utilized for the duration of vital processes to safeguard the product or service from practical organisms and particulate contamination.

No open up-door intervention allowed. In the course of operation, the barriers might not be compromised; lifting the separation may result in contamination and enhanced threat into the solution. Thus, when aseptic operations are performed inside of a RABS, it's the intent to completely eliminate the need to open RABS doorways.

Since closed RABS principles are made use of with harmful and dusty merchandise applications, operators ought to shell out Exclusive interest to cleansing the return air ducts and transforming the prefilters without contaminating them (see Determine six).

oRABS are employed to include filling line devices the two for aseptic and powerful goods processing. This tools is a very realistic to signifies being a containment Alternative for processes like, although not restricted to, milling and sieving applications.

RABS systems are labeled into the subsequent systems: passive RABS, Energetic RABS, or closed RABS. Apart from the closed RABS, the operator generally has access to crucial areas in the RABS. Together with the isolator, access is only attainable employing gloves within the isolator, the same as While using the closed RABS.

Since isolators are commonly located in ISO Class eight cleanrooms, PPE is composed of jumpsuit or plant uniforms; lab coat; head and shoe addresses; and one non-latex gloves. The latter is utilised as a precaution during isolator operation using the glove ports.

From the standpoint of contamination control, no claims have been manufactured that the overall performance of RABS is superior to that of isolators, but relatively that RABS could be simpler to put into practice plus more adaptable from the manner wherein it will allow operator access.

SKAN features its buyers the potential for reasonable mockup more info experiments. These scientific tests have a substantial effect on the design phase of an isolator approach by pre-designing the entire system In line with fact problems inside of a design.

RABS usually are cleaned manually accompanied by a CIP unit to clean up commodities. This process is more simple when compared to the cleaning strategy of an isolator, which incorporates bio-decontamination.

RABS is often labeled as possibly Energetic or passive systems. A passive RABS doesn't have its personal air recirculation, filtering, or conditioning. Its higher-purity air supply emanates from the cleanroom.

The most important details in the draft EU GMP Annex 1 with regard to isolators are illustrated in Determine 1. The starting point for every CCS is the danger observation of the design on the isolator system, such as the set up of kit within an isolator, such as a fill/finish machine for vials, syringes, etcetera. The vast majority of structure failures could come about in the course of the possibility observation of your isolator System. The look kinds The idea for cleansing to be able to stop a feasible particulate or microbiological contamination from the sterile items, or in order to avoid cross-contamination in the situation of a multi-merchandise system.

Determine here 4: Equipment in an Lively RABS. The RABS has its personal air-managing system that pulls air with the area and through openings underneath the item transport.

All interfaces, gloveports, mouseholes, and transfer ports must be integrated to the physical barrier because they separate the clear process area from the potentially contaminated exterior areas.

Media fill and environmental checking needs from the critical zone are equivalent with Individuals for isolators. Checking within the surrounding atmosphere also is required.

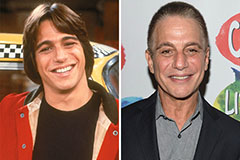

Tony Danza Then & Now!

Tony Danza Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now! Erika Eleniak Then & Now!

Erika Eleniak Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now!